There are a number of techniques or tools that help a manager in effective controlling. The systems architecture document outlines both the hardware and software of the intended solution.

Change Management Business Process Management Change Management Project Management Tools

Actually many processes have 1 of value-added time.

. In a market economy the consumer plays a larger role than the national and state government. Write just enough code to support the automated build continuous integration system and automated test framework in use. Along with each of the hazards there must be instructions for how these hazards should be handled and stored.

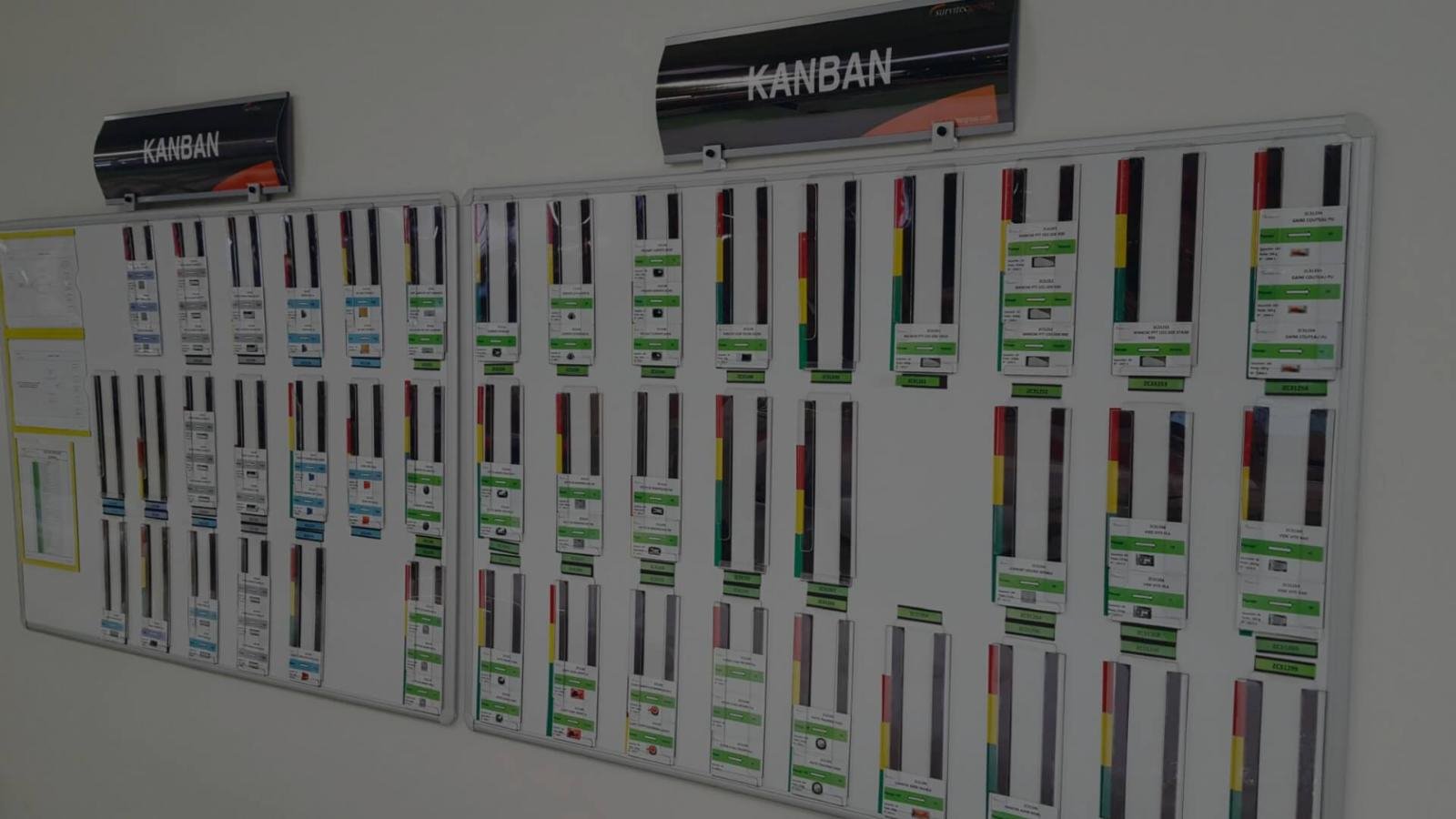

Kanban is a method for regulating the flow of materials which provides for automatic replenishment through signal cards that indicate when more materials are needed. Kanban is a visual method for controlling production as part of Just in Time JIT and Lean Manufacturing. Kanban Cards are one of the many visual controls you can implement.

It contains all of the line items for a full control plan part or product characteristics process controls tests measurement system analysis and reaction plans. Offers simple visual techniques for controlling the flow of materials. For visual controls to be effective there needs to be a clearly defined process for getting support.

HSL and HSLA vs. Your Kanban board will provide you a visual tool to organize your own life and business and soon you will consider it your indispensable personal assistant. Everything you need to know about the techniques of control used by the management.

Manufacturing Deviation A temporary change in production or a manufacturing procedure. The Periodic System vs. The car company applied it to their lean manufacturing model known as the Toyota production system.

Further your education online with a degree from a Purdue University system institution. It forms the foundation of Lean or the Toyota Production System along with the concept of standardized work and Kaizen. The economy is run by.

Learn more about our programs here. Its purpose is to ensure that you only produce what the customer is asking for and nothing more. Major Fire Hazards - All of the major fire hazards that exist in the facility must be identified.

In simpler words a sequence diagram shows how different parts of a system work in a sequence to get something done. Heijunka pronounced hey-june-kuh is a Japanese word that means levelingIn Lean it refers to the leveling of production aimed at improving the flow of a process to better match customer demand reduce waste and decrease or quit batch processing. After successfully completing the SAP HANA Implementation Modelling course delegates will gain skills in implementing information models in SAP HANA replicating data using SAP landscape transformation SLT.

An example is the use of a substitute part. Agile teams use Kanban boards for story-boarding user stories and for backlog planning in software development. RGB and RGBA in CSS Instead of dealing with different color values like RGB the HSL color function allows you to control the saturation and lightness of a specified.

Assets are interfaced to TOPDesk from a source system depending on the service but can also solely exist in TOPDesk. Lean Six Sigma Training Courses combining both Lean and Six Sigma methodologies to create one of the most powerful certifications in business improvement. The Periodic Inventory System.

MES Manufacturing execution system A system that controls and manages production on the factory floor with the goal of reducing the total time needed to produce an order. As part of a pull system it controls what is produced in what quantity and when. For Frontend Developers and Web App Engineers.

Deviations may be planned or unplanned. László Turi Darren Hagmans above historical overview of Lean Agile Scrum and Kanban and the comparison of the relevant pairs is well arranged concise and extremely useful. An assignment matrix facilitates better communication between team members and provides transparency by creating a system to make sure everyone is updated and always on the same page.

Build a better future. They illustrate how the different parts of a system interact with each other to carry out a function and the order in which the interactions occur when a particular use case is executed. Control has a regulating effect.

Our Configuration management System contains serveral CMDBs of which TOPDesk is one. With the dawn of visual planning boards in software in our era like Trello there are now new uses for Kanban tools and Kanban methods. Two other economic system examples are market economies and planned economies.

Most small businesses still use periodic inventory management because it does not require sophisticated software or. The Perpetual System This graphic shows periodic and perpetual systems as a calendar. The Knowledge Academy provide Lean Six Sigma Green Yellow and Black Belt Certifications delivered in classroom in-house virtual and online.

This useful system also performs advanced data queries such as text analysis streaming analytics data processing and many other functions. Visual Controls They cover more broadly how an area works physically matters of where items are located general housekeeping and controlling the flow of production can all be covered by visual controls. A production control plan is used for the full production of a part.

According to the Project Management Institute PMI a methodology is defined as a system of practices techniques procedures and rules used by those who work in a disciplineLean practices Kanban and Six Sigma are project management methodologies. The fields interfaced to TOPDesk will be overwritten whenever the import is. Detailed information such as how the hazards could ignite and what fire protection is needed when working with them should be included as well.

It is important for a manager to know the areas of control and tools and techniques of control. Belaboring communications can bog down a project with too many pointless meetings and confusing interactions in which people try to understand what theyre supposed. Lets kick things off with a project management methodology definition so that were all on the same page.

Important to know is that this is a one-way interface. Most current state value stream maps find that. The technical staff led by the Technical Lead also do the first high level version of system architecture.

This stage will be discontinued once the pre-launch part or process has been validated and approved for production.

Kanban 4 Steps Inventory Control System Sesa Systems

Kanban Pull Systems Ut Center For Industrial Services

Operational Excellence Consulting All Rights Reserved 35 Example Of 5 Whys Why Because 1 W Operational Excellence Leadership Management Lean Six Sigma

Pmbok Guide 5th Edition Processes Flow In English Project Management Project Management Tools Pmbok

Kanban Method Explained Guide 2022

Prince2 Processes Project Management Tools Project Management Professional Project Management

Read More On Tipsographic Com Free Kanban Board Templates For Excel Google Sheets Lean Enterprise Lean Manufacturing Kanban

Gemba Walk Process Stapling Lean Six Sigma Visual Management Lean Manufacturing

Guide To Kanban In Software Development Inflectra

Pin By Tobias On Meta Cognition Agile Software Development Agile Methods Agile Scrum

Hoshin Planning Presentation Visual Management Strategic Planning Process Lean Six Sigma